Responsible Sourcing of Minerals Policy and Due Diligence

Philips efforts to respect human rights extend to issues further down in our supply chain, for instance to prevent human rights abuses in the extractives sector, especially related to conflict minerals. We are committed not to purchase raw materials, subassemblies or supplies, which we know contain conflict minerals.

Responsible Sourcing of Minerals Policy and Due Diligence

Philips efforts to respect human rights extend to issues further down in our supply chain, for instance to prevent human rights abuses in the extractives sector, especially related to conflict minerals. We are committed not to purchase raw materials, subassemblies or supplies, which we know contain conflict minerals.

Conflict minerals is a term used to define minerals mined in conditions where armed conflict and human rights abuses occur. The term typically to refers to four minerals – tungsten, tantalum, tin and gold (also known as 3TG) – that are mined in the eastern region of the Democratic Republic of the Congo (DRC). These minerals are used in the production of various goods such as jewelry and virtually all electronic devices.

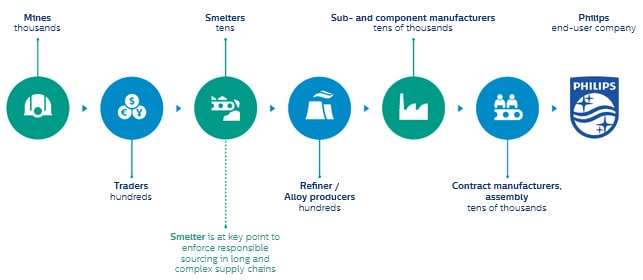

We do not directly source minerals from mines in the DRC or elsewhere, and the supply chain for these metals consists of many tiers, including mines, traders, exporters, smelters, refiners, alloy producers and component manufacturers, before reaching our direct suppliers.

Responsible sourcing of minerals is an important part of our supplier sustainability activities. We are working toward the following goals: We recognize that from our position in the supply chain as a downstream company we are able to have an impact in addressing the sustainability issues related to mining of minerals through implementation of due diligence mechanism and a strong multi‐stakeholder engagement.

To stay aware of early risk warnings, Philips proactively reviews public allegations and incidents based on concerns reported via the externally hosted Philips Ethics Line, Philips website, existing industry grievance mechanisms like RMI and ITRI’s Tin Supply Chain Initiative (iTSCi) as well as other publicly available information. For more information or grievances, stakeholders can also contact us via the Supplier.Sustainability@philips.com e-mail.

Background to Philips due diligence activities

Philips has disclosed the use of conflict minerals since 2009, even before the Dodd-Frank Wall Street Reform and Consumer Protection Act was instated. In 2012, Philips was the first company to publish its list of smelters in the minerals supply chain. Since 2014, Philips annually reports on supply chain due diligence by filing a Form SD and Conflict Minerals Report to the U.S. Securities and Exchange Commission (SEC). The complete Philips Conflict Minerals due diligence framework, measures and outcomes are described in the Conflict Minerals Report.

Our conflict minerals supply chain due diligence program is designed in line with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and its supplements (OECD Guidance). Drawing upon the Five-Step approach described in the OECD Guidance, we established a system of control and transparency over 3TG supply chains by creating a process to engage suppliers, assess their due diligence efforts, and identify smelters.

Smelters mix minerals from many sources and refine them into metals used in our industry. The smelter is at a key point in the supply chain to enforce responsible sourcing – by exercising due diligence in selecting their mineral sources. The Responsible Minerals Assurance Process (RMAP) identifies smelters that can demonstrate, through an independent third-party assessment, that the minerals they procure do not originate from sources that contribute to conflict in the DRC, adjoining countries or global Conflict-Affected and High-Risk Areas.

As sufficient validated conflict-free smelters for all four metals become available, we will direct our supply chain towards these smelters. We regularly update the Philips smelter list with new information received from our suppliers and request the identified smelters to participate in the RMAP. Latest results are part of Philips’ annual report.

We recognize that due diligence is a continuous process and continue the efforts of actively steering our suppliers toward conflict-free smelters in our supply chain management. We have also made responsible sourcing of minerals a supplier contract requirement and one of the supplier assessment topics in the Supplier Sustainability Performance program.

Other due diligence initiatives

Since 2020, Philips expanded the scope of its due diligence program to include cobalt as a new material. Although not included in “conflict minerals”, or subject to existing mandatory due diligence requirements, this mineral is increasingly associated with severe human rights violations (such as child labor). As part of this expansion, we engaged suppliers that provide materials containing cobalt. In our first year (2020), we reached a 100% response rate. In addition, we performed smelter outreach on several occasions. Where appropriate, we worked with direct suppliers to facilitate alternative sourcing.

Downloads

Beyond due diligence – multi‐stakeholder initiatives and on-the-ground projects

From our position in the supply chain as a downstream company, we believe that a multi-stakeholder collaboration in the responsible sourcing of minerals is the most viable approach for addressing the complexities of minerals value chains.