Interview with Kadir Yildiz, system engineer at Philips Refurbished Systems

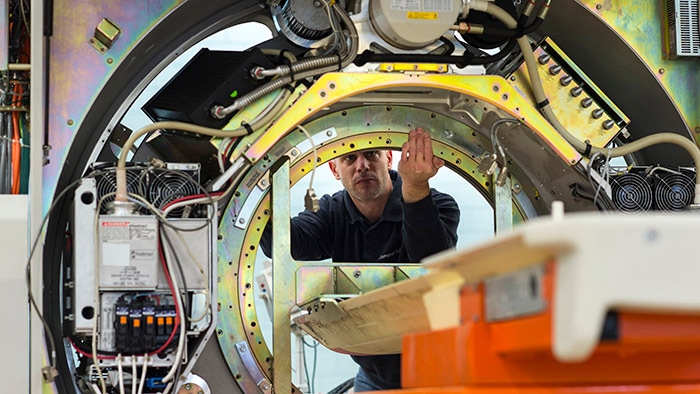

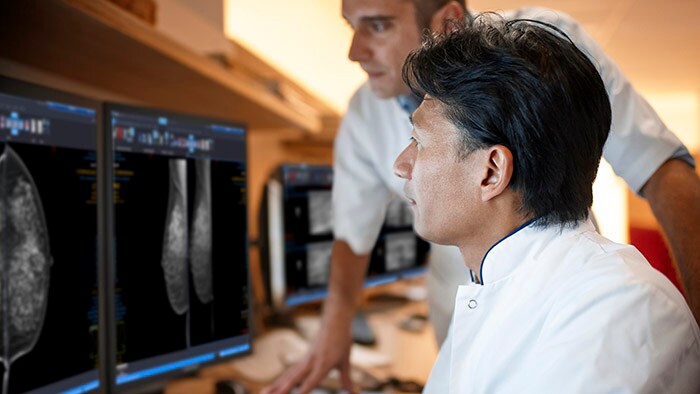

* This article was orginally written in Dutch by the staff of RTL Nieuws as part of their series “They keep the Netherlands running”. You can find the original article here. These are extraordinary times. In this series we let the people who keep our society running tell their stories. Today it’s Kadir Yildiz (47), a systems engineer at Philips Refurbished Systems in Best in the Netherlands. Together with his colleagues, he works in a large factory producing CT scanners – machines that, among other things, allow hospitals to capture images of people’s lungs. "There’s a large mobile tent in the parking lot of the OLVG hospital in Amsterdam, the Netherlands. Inside the tent, there’s a CT scanner that allows doctors to quickly take pictures of a people’s lungs to help determine whether or not they have coronavirus. We're taking back old CT scanners that hospitals have been using for nine, ten years. We give the system a hardware and software update so the scanners work like new, and then send them back to the hospital. That’s the work of me and my colleagues. I'm quite proud of that. We've worked very hard, all of us.

Sometimes it's hard to leave home, but my children can always call me. That's what they do. "Dad, can you help me with the math?” I'm good at math.

Normally, we need about six weeks for one scanner. Now only two. We all feel there's a rush. Nevertheless, we work no less stringently, but focus on the software and not on the outside of the machines. Whether there's a scratch on one of these scanners isn't important now. Making sure that the hospitals get the equipment they need, that's what it's all about. The location in Best where we work is gigantic: equivalent in size to around 80 football fields and employing more than 3000 people. And we’re extra busy these days because of coronavirus. Hospitals all over the country are setting up mobile units. They also need a scanner. We'll take care of that. A scanner like that is big. Normally, if you're lying in it, you can't see it, it's got a neat hood over it. But a typical scanner weighs around 1.5 tons, as heavy as a car, and spins around your body four times a second.

People never really have an image of my work. My children, I have five of them living at home, never really knew what daddy was doing. But now it's different. They see me leave every day, while they stay at home with my wife and have to do school work there. The other day, my seven-year-old daughter asked: “Daddy, if we can't leave our houses anymore, will you stay home too? Then my son of 10 answered: “No, daddy has an important job, he has to help with the care”. I liked that. Sometimes it's hard to leave home, but my children can always call me. That's what they do. "Dad, can you help me with the math?” I'm good at math. I'm working longer than usual now, because the situation calls for it. I'm doing what I have to do and what I can do. I'm kind of proud that I’m able to help the healthcare workers at the frontline a little now. I'm always a bit in the background, not liking interviews and stuff, but now I see that it's important we keep working. I'd like to help right now."

Share on social media

Topics

Contact

Joost Maltha

Philips Global Press Office Tel: +31 6 10 55 8116

You are about to visit a Philips global content page

Continue